BFM fitting: Flow Correction

Some powders can be hugely abrasive when flowing through the BFM® fitting, causing excessive wear and tear. There are also instances where the flow of powder is entering the BFM® fitting from an angle, causing abrasion to the wall of the BFM fitting connector. Flow correction can be a wonderful solution to this problem.

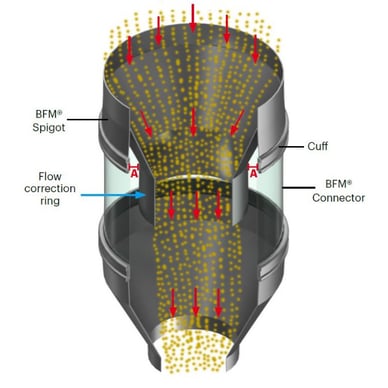

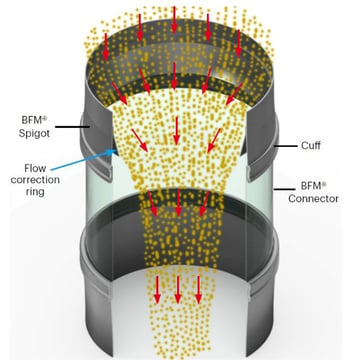

To avoid this problem, the best way is to redirect the flow of the product slightly, often with a ‘flow correction ring’ to avoid direct contact with the connector walls as much as possible.

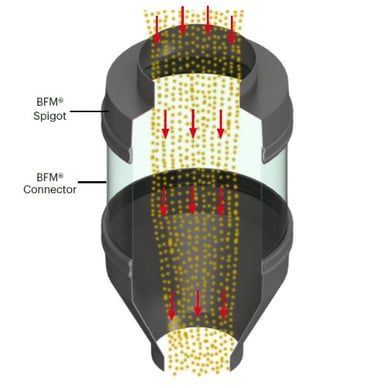

There are three ways to complete proper ‘flow correction’, and you can see the three ways below to avoid sleeve degradation.

| Method 1: Larger diameter BFM spigot vs. pipe | Method 2: Flow ring extends inside connector | Method 3: Flow ring finishes before spigot cuff |

|

|

|

For example, the video below highlights Method 2 to facilitate the flow of coffee beans through the BFM fitting connectors.

BFM fitting Flow Correction

Our engineers are well versed in these various flow correction options, so if you have questions about these tactics to avoid BFM fitting sleeve degradation, feel free to fill out the form below and we can discuss your questions and options