USDA Dairy Acceptance on MAGNATTACK™ Magnetic Separators

Chanhassen, MN December 9th, 2015 – Powder-Solutions Inc., USA distributor for MAGNATTACK™ and other sanitary powder processing equipment, is proud to announce MAGNATTACK™ Global receiving USDA Dairy Acceptance on four models of sanitary magnetic separators.

The four models that received USDA Dairy Acceptance include the RapidClean™, Round Pipe Separator, Mag-Ram™, and Powder Transfer Magnet.

Ultimately, the goal of obtaining USDA Dairy Acceptance for these items was to reinforce to customers in the United States and around the world the commitment that MAGNATTACK™ has towards designing and manufacturing components to the highest grade of sanitary standards. “USDA Dairy Acceptance offers peace of mind to our customers that we’ve taken great measures to ensure the sanitary design and execution of our equipment, and to align ourselves with our customer’s ultimate goal of product safety,” said Marv Deam, CEO of Powder-Solutions, Inc.

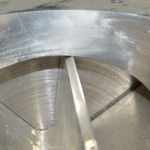

USDA’s review and final acceptance involved an on-site inspection completed by a USDA AMS Dairy Grading Branch inspector, who checked that the construction met the requirements of the USDA Guidelines for the Sanitary Design and Fabrication of Dairy Processing Equipment. This included a thorough inspection the equipment, ensuring that all product contact surfaces were finished to the required smoothness, were free from pits and crevices, had the required radii in corners, and was accessible for cleaning and inspection. “While the design of equipment can be reviewed over drawings, the execution of welding, polishing, and assembly can only be inspected on actual equipment. This is a key requirement of the USDA Dairy inspection process and assures that a manufacture can execute the design and fabrication to meet the guidelines.” said Scott Lodermeier of Powder-Solutions, Inc. While many magnet separator manufactures may claim “sanitary construction”, that means different things to different industries. The USDA Dairy Acceptance certificate is proof that MAGNATTACK™ has submitted designs that passed a physical inspection as well.

The RapidClean™ line of easy-clean sanitary grate magnets can be installed at rotary valves, screw conveyors, bag dumps and bulk bag unloaders, or upstream of packaging operations and bulk filling systems. Sanitary design is achieved by the use of ledge free housing interior, and seal welded, vacuum encapsulated magnet rods. The design of the RapidClean™ provides quick access to magnets for cleaning. The magnets are supported by a slide and hinge mechanism that supports the magnets outside of the product stream during inspection and cleaning, improving operator and product safety. Older grate magnets and housings required the operator to remove the grate and set it down safely for inspection, running the risk of damage to the magnet or injury to the operator. A special cleaning tool allows easy removal of collected metal. No more “taping the magnet” to remove collected metal.

Round Pipe Separators are designed for use in dry processing for powder transfer lines in pneumatic conveying systems. The design of the housing maintains product velocity and aerodynamic flow around the magnet rod with minimal pressure drop. A Tri-Clover ferrule holds the magnet rod in place, allowing tool-free disassembly for quick magnets inspections.

MAG-RAM™ self-cleaning sanitary grate magnets are a significant addition to powder processing lines that are difficult to access, ones that must be checked frequently, or processes that require minimal exposure to ambient conditions. Product security is achieved by the self-cleaning magnet rods retracting in and out of the housing, while rotating to avoid material buildup and wear on the magnet rods. Magnet rods can be programmed for simultaneous or staggered cleaning. Collected metal drops into a sealed container, eliminating operator contact with the magnets or powder process stream.

Powder Transfer Magnets’ unique design is used specifically for pneumatic conveying installations, providing superior magnetic separation by utilizing dual aerodynamic “tear drop” magnet rods. This dual rod design provides exceptional coverage as powder flows through the unit, and maintaining a low pressure drop. Tri-Clover ferrules hold the magnet rods in place, creating a dust tight design and allowing tool-free disassembly for quick magnets inspections. Old fashioned inline magnets utilize a magnet assembly inside an outer sleeve. Not only is that design unsanitary, heavy and cumbersome, but the magnet strength is greatly reduced, and the pressure drop is significant. Product degradation is significant on fragile products. Powder Transfer Magnets was the solution to those problems.

“MAGNATTACK™ offers unique designs not seen from other magnetic separator manufacturers in the USA”, says Lodermeier. These designs, together with superior sanitary execution, make MAGNATTACK™ an excellent choice for the food, dairy, nutritional and pharmaceutical industries.

Powder-Solutions Inc. is available to provide quotes and supply more information about MAGNATTACK™ magnets and how their technology is changing the magnetic separation world. They can be reached at sales@powder-solutions.ckstaging.com or 877-933-2556.