Diverter Valves

Convey Line Divert Valves

Powder Process-Solutions offers a wide range of diverter valves which provide methods for directing product from a single inlet to multiple outlets, or from multiple inlets to a single outlet. Designs can accommodate gravity flow as well as pneumatic conveying pressure.

Diverter valves are available in manual designs, which keep costs low and are appropriate for systems with less need for product changeover, as well as automatic designs, which feature a panel with an automatic diverter valve necessary in large plants or in situations with recurring product changeover.

Our product line of diverter valves includes

- Rotary tube selector valves

- Y-type divert valves

- Fill vent (scale divert) valves

- Gravity divert valves

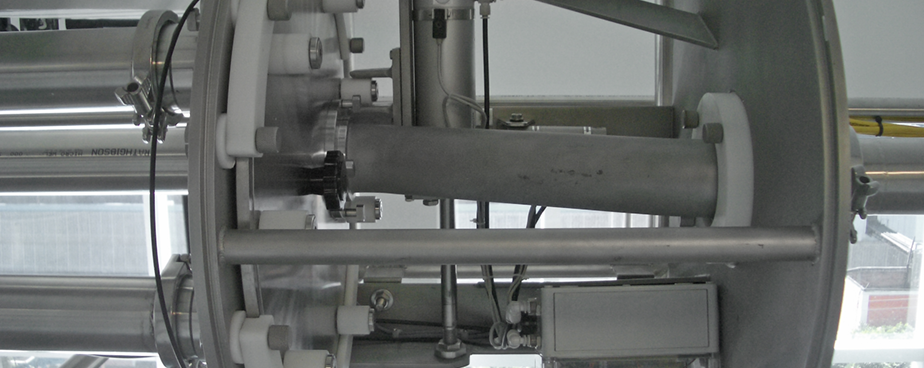

Rotary Tube Selector Valves

Rotary tube selector valves are used in dilute or dense phase pressure and vacuum pneumatic conveying systems to divert flow stream to either one or multiple destinations or used in reverse to combine multiple sources to one destination.

Rotary tube selector valves are suitable for use on powders fragile to abrasive and high pressures applications.

Y-Type Divert Valves

Y-type divert valves are used in dilute phase pressure and vacuum pneumatic conveying systems to divert flow stream to one of two destinations or used in reverse to combine two sources to one destination.

Y-type divert valves are appropriate for applications focused on non-abrasive powders and cheese curds.

Fill Vent (Scale Divert) Valves

Fill vent valves are used to divert powder flow in pneumatic conveying systems. They are specifically designed to divert powder flow directly into hoppers while the convey air is vented further down line to another vessel with a bin vent filter. In scale hopper applications, the valve diverts rapidly when a set weight is reached, with the remaining powder in the line conveyed back to the source silo.

Fill vent valve designs are compact and simple, with few moving parts.

Gravity Divert Valves

Gravity divert valves divert gravity-fed material into one or two lines, completely closing off the unused port by means of a rotating blade. Our superior designs not only avoid dead spots, which allows material to flow unrestricted through the valve, but also offer tool-free disassembly for quick and easy cleaning and changeover.

Depending on the location and the application of interest, our engineers can design and install the appropriate diverter valve to successfully keep your product line flowing. Material construction is dependent upon plant requirements. Valves that meet USDA Dairy sanitary standards along with those that meet 3A sanitary standards are available for sensitive applications.