Mixing and Blending

Mixing & blending systems are an essential part of many powder processing systems. Proper mixing systems target efficient and effective processing to achieve a homogenous product while providing consistent quality throughout to the end product. To achieve this, food and dairy powder processors must understand the importance of analyzing and understanding both product requirements and mixer specifications.

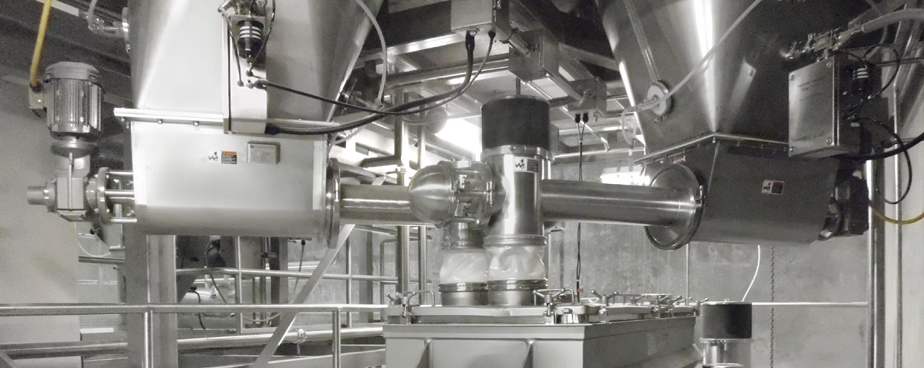

PPS offers a versatile variety of powder mixers and blenders designed specifically for sensitive dry products such as dairy powders, nutritional powders, and food products. PPS selects and integrates the appropriate mixer design suitable for each specific powder and processing requirements. By selecting the appropriate mixer design appropriate to each product and process requirements, the user experiences low powder degradation while obtaining a high level of uniformity.

Various brands and types of blenders include:

- Ribbon Blenders

- Continuous Blenders

- Twin Rotor Blenders

- Pneumatic Blenders

To integrate the appropriate mixer or blender, PPS establishes a reasonable timeline for delivery of ingredients to the mixer and discharge of the blend from the mixer. The proper feeding equipment is established to support the timeline while maintaining the highest level of accuracy. Select blending technologies and blender size are then analyzed to achieve homogeneity within those timeline parameters. Evaluation then takes place to establish product degradation, heat build-up, sanitation, and other potential concerns for the mixing system.

PPS combines system knowledge and experience with leading blender manufacturers’ products to ensure high throughputs, superior homogeneity, and rigorous sanitation standards are upheld before, during, and after mixing and blending takes place.

When required, testing can be performed at our in-house test facility to ensure all standards and blend requirements are met.

At Powder Process-Solutions, we will:

- Establish a reasonable timeline for delivery of ingredients to the mixer and discharge of the blend from the mixer

- Select feeding equipment to support the timeline, while maintaining accuracy

- Select blending technologies and blender size to achieve homogeneity within the timeline parameters

- Evaluate product degradation, heat build-up, sanitation, and other potential concerns

Request a Quote

Powder handling is more than just putting components together. At PPS, we design custom, sanitary solutions for your valuable powder. Fill out your information to the right and we will contact you within one business day to discuss your powder processing needs.