Can You Risk A Product Recall Due to Tramp Metal?

The average powder processing facility has 11,562 moving parts. OK, so that statistic is made up! But in all seriousness, a powder processing facility is full of sophisticated technological equipment. When choosing equipment, plant engineers and managers have a plethora of decisions to make. By the time they get to magnetic separators, it may be just another item to check off the list.

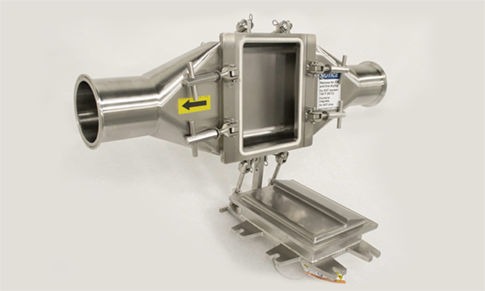

However, magnetic separators need careful consideration. Magnetic separation is an increasing focus throughout the bulk powder handling industry, and rightfully so. From inline magnets to grate magnets, rotary magnets to plate magnets, there are many different designs suitable for various applications. Magnetic separators protect product and  equipment and offer peace of mind.

equipment and offer peace of mind.

Ensures Product Safety

The first safety investment a magnetic separator offers is to the product itself. Powder processing managers know that the integrity and safety of the product is imperative. Product safety requires ensuring the efficient, thorough removal of all ferrous tramp materials. By choosing high strength, well-built magnet separators, plant managers are able to protect their product from the contamination that can come with tramp metal exposure.

Protects Downstream Equipment

An often overlooked benefit of strong, application-appropriate magnetic separators is the protection of downstream equipment. By installing a suitable magnet or set of magnets, managers eliminate the potential for tramp metal, both large and small, to travel throughout the processing system. Even small metal fragments can potentially damage finely tuned downstream equipment. Rotary valves and other components can be jeopardized by foreign materials, which may damage precision tolerances that are important to efficient processing.

Offers Peace of Mind

Magnetic separators also give plant managers an investment that is intangible – peace of mind. They have the assurance that ferrous metal fragments are unable to damage downstream equipment. They know that product is protected from contamination. They appreciate that the company’s reputation is secure. That must be worth 11,652 good nights’ sleep. Give or take.

Download our brochure to learn how a spherical pipeline magnet helps powder processing facilities remove metal fragments from product flowing up or down, up to 12,000 gauss strength, to reinforce product safety.