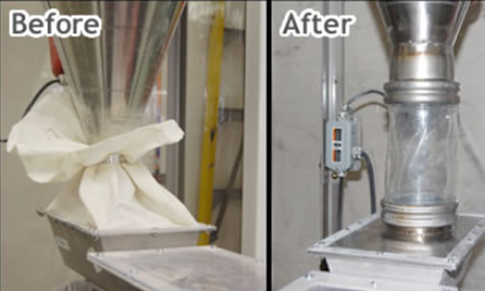

BFM® Fitting A Breath Of Fresh Air For Bulk Powder Processors

Amedica, a medical technology company, uses medical grade silicon nitride ceramic powder to create revolutionary spinal implants. When processed, this fine‐as‐talc powder infiltrated processing equipment connections and created a consistently powdery atmosphere.

“Our bulk powder processing facilities transform nitride ceramic from powder into spinal implants improving the health of thousands,” states Jeff Goodell, Director of Facilities and Maintenance for Amedica. “Ironically, the sand cloud created during this processing threatened the health of my employees.”

Nothing Could Stop The Powder Cloud – Not Even Duct Tape

“Rubber hose clamps around everything from silicon sheets, to fabric, to duct tape,” laughs Goodell. “We tried everything to contain this powder in the connections between our processing equipment. Ultimately, it was too fine to hold.”

Whether Amedica sent powder through a vibrator, down a chute, or sifted it through a mesh, the cloud would always appear.

“Expensive respirators had to be worn by all employees to minimize the risk of powder inhalation,” continues Goodell. “To ensure a sanitary environment, our employees also spent nearly six hours every other day scrubbing caked‐on powder off processing equipment.”

|

If It Can Hold An Explosion, It Can Hold Our Powder

At the 2008 National Safety Council Congress and Expo in California, Amedica Safety & Hygiene Manager David Echols walked by a booth for Powder‐Solutions. It was there that Echols discovered the BFM® fitting.

“The DVD I saw of the BFM® fitting in action simply blew me away,” states Goodell. “The BFM® fitting, essentially a clear polyurethane sleeve and spigot system, was able to suppress what looked to be a major powder explosion.”

Explosions are a risk in bulk powder production facilities as airborne powder can become volatile fuel in the presence of an ignition source. While traditional hose clamps failed to contain the explosion, the success of the BFM fitting shown in the video proved to Goodell that the BFM® fitting was the solution

for Amedica.

“If it could hold an explosion,” states Goodell, “It could hold our powder.”

|

The BFM® Fitting Is The Perfect Fit

“I began consulting with Jeff and Amedica soon after 2008’s National Safety Council Congress and Expo,” states Marv Deam, CEO of Powder‐Solutions, distributors of the BFM® fitting. “Our consultation began with the two of us sharing detailed drawings back and forth.”

Goodell’s drawings were illustrations of the powder production plant layout at Amedica, detailing both the work environment and the process equipment.

“Once I received Goodell’s drawings, I drew specs showing how the BFM® fitting would be customized to securely connect each piece of equipment,” states Deam.

After merely two weeks of consultation, Deam and Powder‐Solutions customized a BFM® fitting system, which included spigots and replaceable sleeves, for the bulk powder processing facilities at Amedica.

Zero Powder Infiltration

“Within two days, I had welded the BFM® fitting spigots onto my equipment and was up and running,” continues Goodell. “Deam assured me that once the spigots were welded into place, the BFM® fitting sleeves could be installed within minutes, but I was able to beat that estimate. I had the sleeves snapped in place within seconds.”

While easy snap placement was convenient, it would mean little if the BFM® fitting did not solve the primary problem experienced by Amedica. Quite simply, the BFM® fitting had to prevent powder from escaping between bulk powder processing equipment connections.

“From the day I first turned on our bulk powder processing equipment with the BFM® fitting installed, I was amazed,” continues Goodell. “There was no more sand cloud and absolutely zero powder infiltrated from the sleeve.”

“From the day I first turned on our bulk powder processing equipment with the BFM® fitting installed, I was amazed,” continues Goodell. “There was no more sand cloud and absolutely zero powder infiltrated from the sleeve.”

Zero powder leaking between powder processing connections also eliminated six hours of cleaning every other day. Not only were Amedica employees working in a more sanitary environment, labor costs were cut as frequent cleaning was no longer needed.

Works Like A Champ

After several months of daily use, Goodell reports the BFM® fitting is containing powder as well as it did during the first day of implementation.

“As my employees no longer have to work in sandy air, there is a very real chance based on testing results we will soon approve them to work without the need for respirators,” continues Goodell. “This would save me a significant amount of money on respirator cartridges.”

While the potential for additional cost savings is promising, Goodell is happy with what Amedica is currently seeing in terms of return on investment.

“The BFM® fitting works like a champ,” concludes Goodell. “I don’t know how to else to say it.”